|

|

|

We supply

Integrated Intelligent Machine Vision

Solutions for the following

industrial automation applications: |

|

|

|

|

-

Quality Control of

industrial products |

|

|

- Automatic Sorting

and Grading |

|

|

- Automated Machining

|

|

|

- Machine Learning and

Reasoning |

|

|

- Robot

Trajectory Planning |

|

|

- Robust Visual Target

Tracking |

|

|

- Geometric 2D/3D

Vision |

|

|

- Infrared Thermal

Inspection |

|

|

-

Melting Process Control |

|

|

|

|

|

We try to pursue

and observe the legislated regulations of international

societies and associations to integrate standard products. Our

systems are

adopted to work in automated production lines. In a structured

control system, they communicate with other distributed PLC or

PC-based controllers through industrial digital networks. |

|

|

|

|

|

|

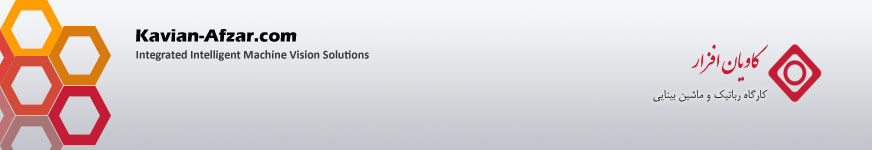

Machine Vision for

Inspection of Industrial Products

|

|

Industrial production lines are equipped with automatic visual inspection workstations in order to qualify the technical specifications

of artifacts and defect detection. In the qualification process, visual features of products are examined and controlled with integrated machineries.

The inspected features are shape and size, color or texture of plant productions.

Machine Vision makes the examining process of these features more reliable.

It’s also a low cost and high performance solution for quality control.

In an intelligent machine vision solution,

the mechatronic part of system handles products to be aligned correctly in the field of view of optical imaging devices

(camera/scanner). Sequential images are captured by the electronic part of imaging subsystem (frame grabber) and software system processes

these images to extract the required features. There are machine learning and test and measurement software modules to make a reliable

decision about possible defects. Finally system’s mechatronic controls the actuators to apply the test results. This sequence is arranged

in a real-time controlled loop to be executed repeatedly. Kavian Afzar Co. has been designed and developed this solution in the

KA-MVIS-1038

system structure:

|

|

|

|

|

|

|

|

|

KA-MVIS-1038R System Structure |

|

|

|

Application of Machine Vision in Metal Sheet Quality Control

|

|

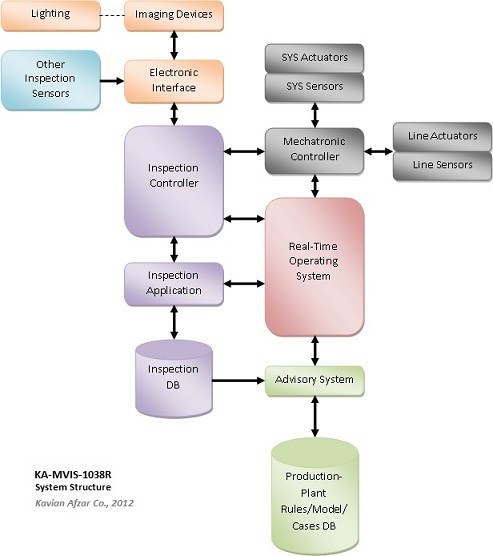

Inspecting surface of metal sheets to find and label

the pre-defined defects is an example of machine vision

application in casting process.

The defects of casting are small cavities, crashes, scratches etc.

Inspecting and control panel can classify these defects and label them to grade the plant’s productions.

|

|

|

|

|

|

|

Copper Sheet Defects |

|

|

|

|

Metal sheet surface is captured by cameras and the classified defects of manufacturing or material itself are

recognized and labeled. Geometric specification of defects

and texture features of metal sheet are archived

simultaneously. You should consider that there are some

constraints in sampling time related to the camera's frame

rate, image processing and decision making periods. The

machine vision systems is equipped with

ASHALogic 2.0

Advisory system to solve the manufacturing problem.

|

|

|

|

Automatic Sorting and Grading

|

|

Mechanical mechanisms are used widely in sorting and grading applications.

These mechanisms are reliable but not smart enough to make intelligent decisions.

Moreover, design of combinational sorting systems is complicated by different requirements of production process.

Typical tasks of Machine Vision systems are inspecting,

grading, sorting, monitoring and guiding in these cases.

Therefore a control panel can perform so many duties just by

camera sensors and electronic interfaces. There some

challenges in optical sorting. For example in fruit grading,

vibration and rotation of fruits under field of view of

camera is a constraint for reliable sorting. |

|

|

|

Sorting and Grading of Ceramic Tiles

|

|

Human eye can detect a small amount of color degradation of ceramic tiles when are floored

continually.

This is a trouble for tile manufacturers that should be take

care of their customers' satisfaction. |

|

|

|

|

|

|

|

|

Ceramic Tiles Color Inspection |

|

|

|

Color sorting of tiles is dependent to

diffuse and uniform illumination. Some optical filters

are used to regulate the spectrum of unwanted reflections. CCD sensor of cameras are examined

for detectable color regions.

|

|

|

|

Automated Machining

|

|

Welding, cutting, trimming, painting and handling are guided with

2D/3D robot vision solutions. Kavian Afzar Co. has developed a

Robot Vision Solution to overcome robot’s trajectory planning.

Vision Guided Robots can handle parts and materials in their work space.

Expert Robots can perform precise operations that could be a great labor for well trained workers.

Vision guided robots carry out the automated machining

efficiently with the following advantages:

- Minimum waste and rework tasks

- Maximum reliability to well done duties

- Uniform output results

- True applied technical standards

- Working in hazardous environments

KA2001 provides a stereoscopic view for robot’s path assigning.

Actually it is a geometric vision system that provides feedback for the motion and position control of robot.

|

|

|

|

Infrared Thermal Inspection

|

|

Thermal imaging is used as a non-contact temperature sensing method. Kavian Afzar has introduced

the

Infrashot System as an automatic temperature mapper for Infrared Thermography inspection.

It's used in predictive maintenance and condition monitoring test methods. It can be used as a real-time temperature profile processing module

too.

|

|

|

|

|

|

|

|

|

|

Remapping an Isotherm to different temperatures in a sample thermogram |

|

|

|

|

|

|

|

|

Filtered and reduced color images from sample thermogram |

|

|

|

|

Since Infrashot is commonly used in automated examining

of thermeograms of heated objects,

the annealed metals or ceramics, backed foods, glass meltings, electrical panels,

fueled engines and many other heated objects can be inspected by

this thermovision software application.

|

|

|

|

|

|

|

|

|

|

|

Please Explore

our all products and services to upgrade your plant's

manufacturing or QC technology with Machine Vision solutions!

Contact us

for more technical details.

|

|

|

|

|

|

|